The content of the article and its materials originate from the WeChat public account ID “Laser Manufacturing Research”.

Abstract

Laser welding, as a high-precision, high-flexibility, and deep-penetration joining technique, has garnered widespread attention from both the academic and industrial communities. To date, the lack of repeatability and stability is still considered a key technical barrier hindering its broader application, especially for demanding high-value products. One important method to overcome this significant challenge is the combination of in-situ monitoring and artificial intelligence (AI) technology, which has been explored extensively in research work. The primary goal of monitoring is to collect basic information about the process and to enhance understanding of the complex welding phenomena that are occurring. This paper first introduces research progress in in-situ optical sensing, behavior characterization, and process modeling during dynamic LBW (Laser Beam Welding) processes. It then focuses on the introduction of optical radiation technologies such as multispectral photodiodes, spectrometers, pyrometers, and high-speed cameras, which are used to observe physical phenomena like laser melt pools, keyholes, and vapor plumes. Particularly, advanced image/signal processing technologies and machine learning models are proposed to identify correlations between process parameters, process features, and product quality. Finally, main challenges and potential solutions are discussed to gain a deeper understanding of the objectives that still need to be achieved in the field of process monitoring in metal-based LBW processes. This comprehensive review is intended to provide state-of-the-art references for those seeking to introduce intelligent welding capabilities as they are improving and controlling welding quality.

Introduction

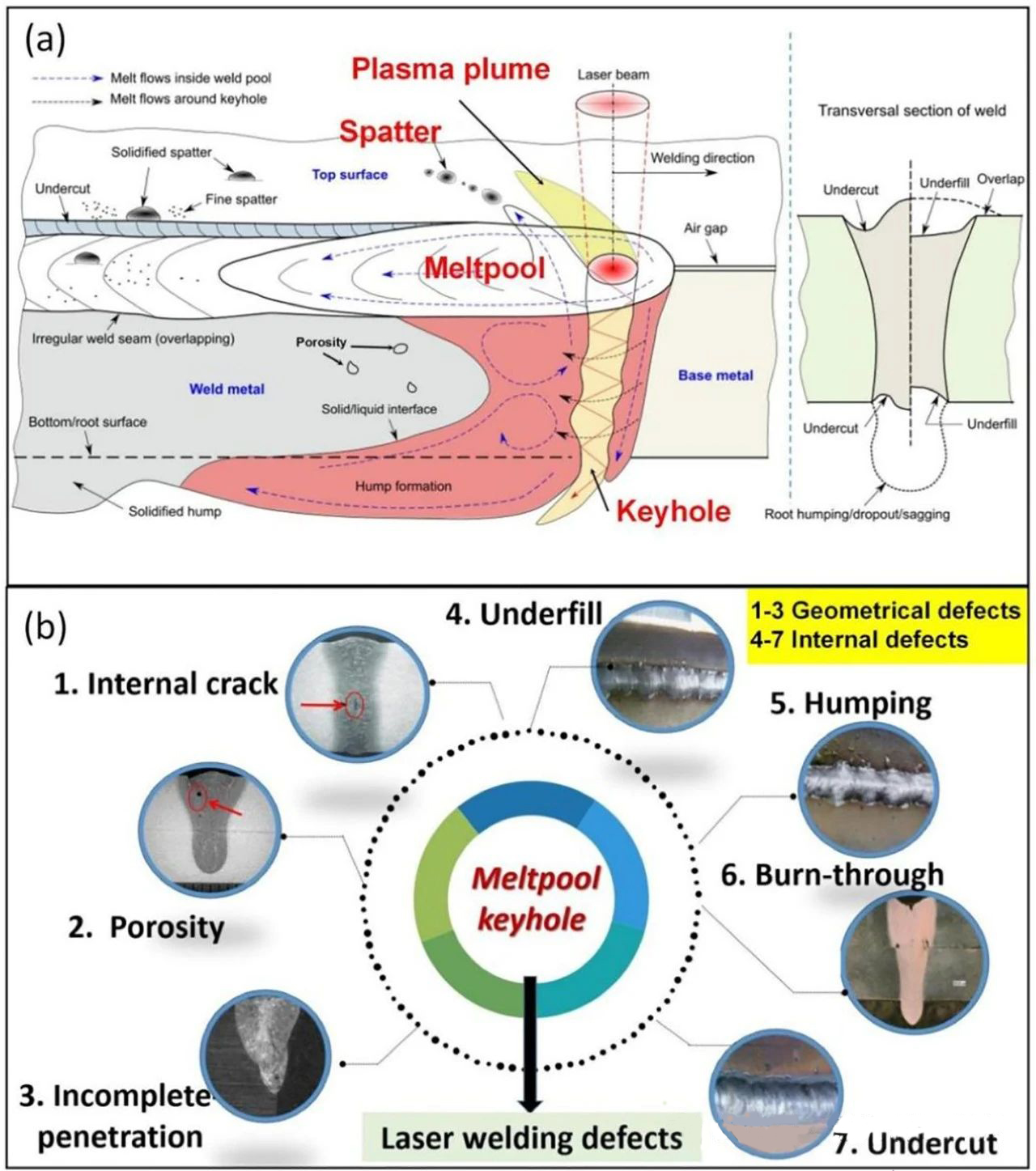

Compared with traditional arc welding techniques, laser beam welding (LBW) has shown significant advantages in achieving automated manufacturing processing, high-efficiency production, and obtaining high-quality welds. In addition, LBW is popular as a promising joining technology with deep penetration depth, high accuracy, low distortion and good flexibility. As an advanced manufacturing technology, LBW has been widely used in various industrial fields, from small hand welding to fully automated welding in automotive, aerospace, shipbuilding, and electronics manufacturing. However, LBW involves many complex physical processes, including metal melting/solidification, pore formation, and laser-metal interactions, resulting in very complex transport phenomena, so the final weld quality is susceptible to several process variables and defects, including high levels of defect porosity, instability, and metal spatter. Potential welding defects can significantly weaken the mechanical properties of welded components and increase the risk of component fatigue, resulting in substandard welded products.

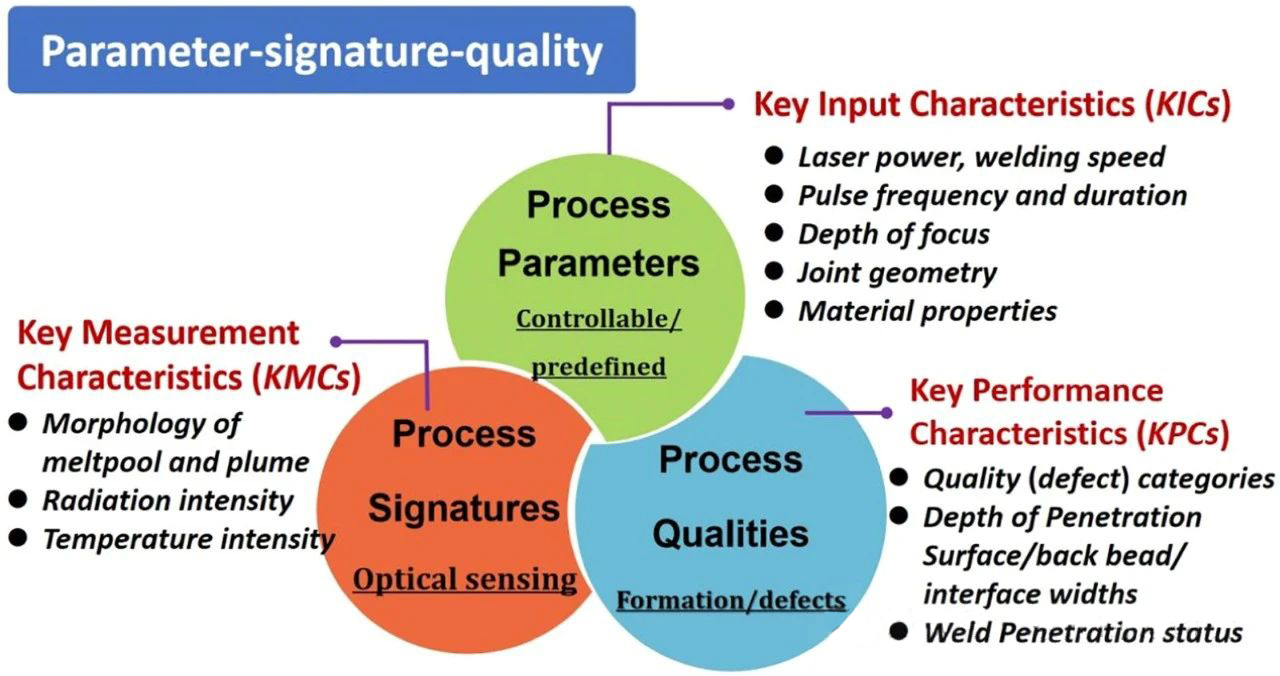

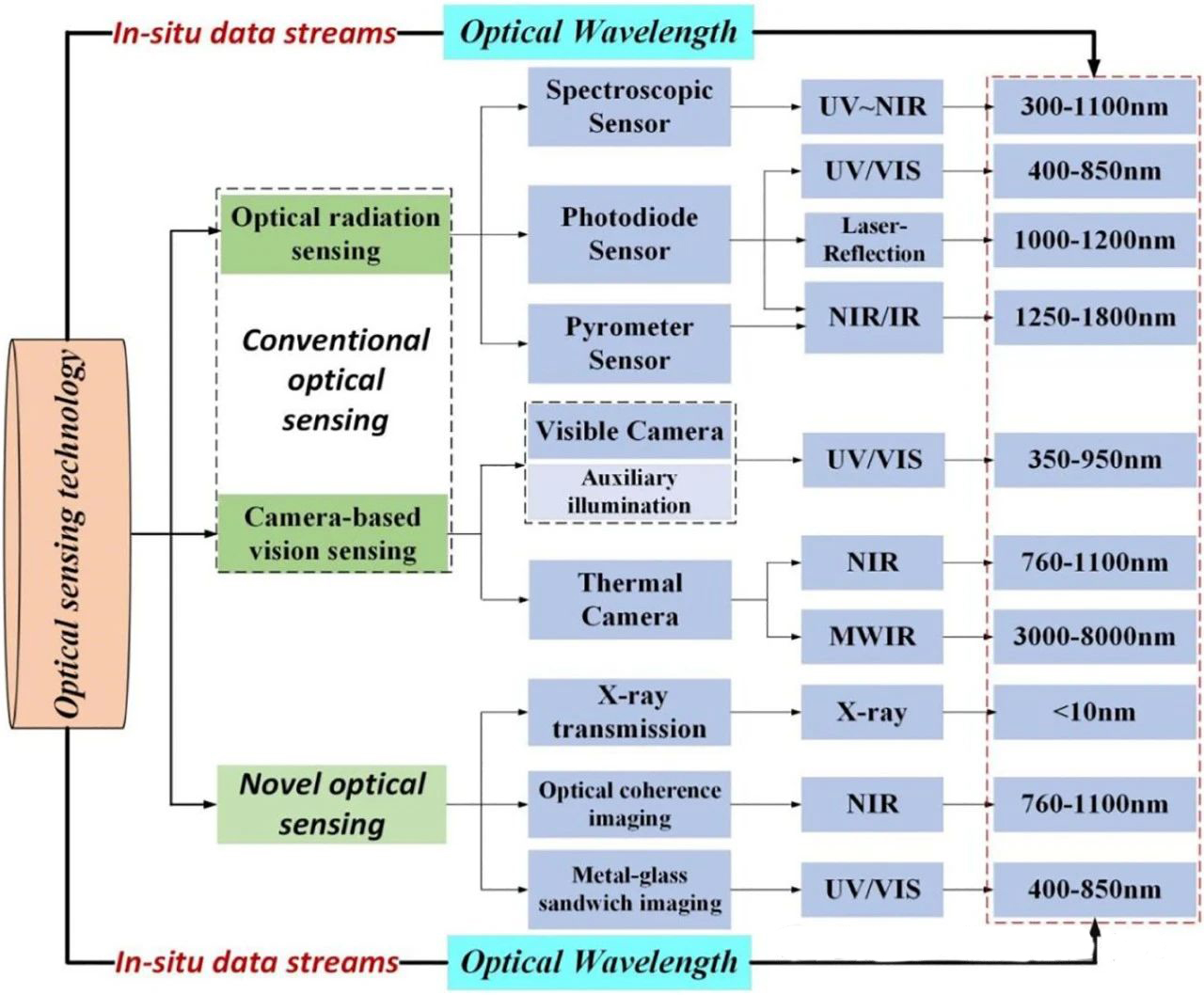

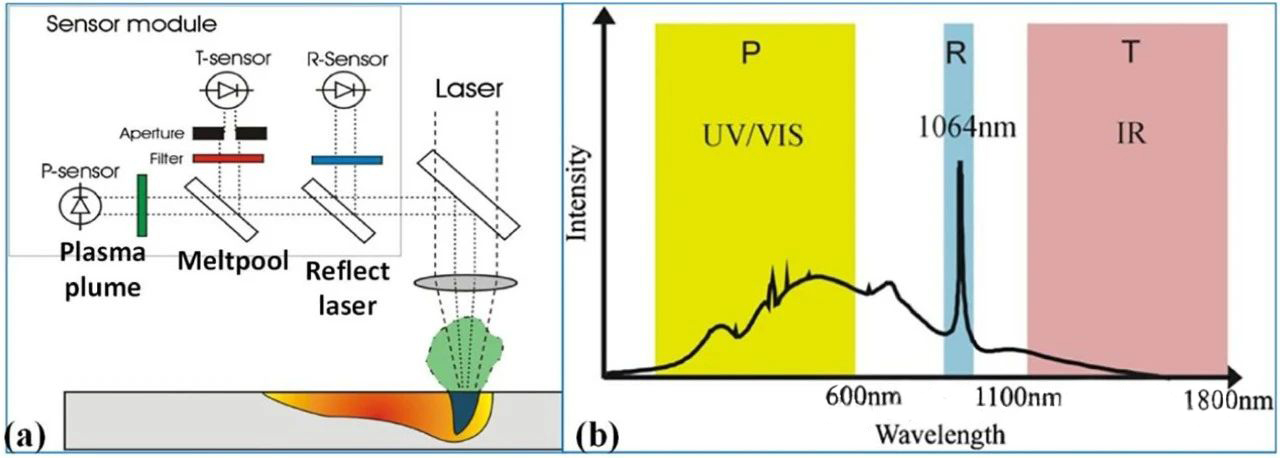

In order to improve product quality and suppress welding defects, and to further better understand the complex phenomena that occur during welding, a series of on-site monitoring methods are proposed to provide valuable information for characterization process and control. Quality. The design concept of mainstream monitoring solutions relies heavily on the use of laser physics generated by laser-metal interactions, including melt pools, pores, and plumes. These physical phenomena carry various types of welding information, such as acoustic emission, electricity, thermal radiation, and visual signals, which are closely related to the welding process and joint quality. Therefore, the correct use of various monitoring sensors and systems is a key issue in accurately describing the laser welding process. For example, microphones or piezoelectric elements are used to collect airborne and structure-borne acoustic emission (AE) signals. Vision sensors including charge-coupled devices (CCDs), complementary metal-oxide semiconductors (CMOS), and high-speed cameras with special filters are used to capture images of melt pools, plumes, and spatter. Spectrometers and photodiode-based sensors are utilized to collect optical signals including visible (VIS), infrared (IR), and ultraviolet (UV) wavelengths. Near-infrared (NIR) cameras and pyrometers can be used to collect heat signatures emitted by the weld area. Sophisticated monitoring systems often consist of these sensors, which allow for a more comprehensive collection of various types of welding information.

In recent years, a number of published reviews have introduced the effective application of various advanced sensing technologies (i.e., vision cameras, acoustic emission, ultrasonic testing, and eddy current techniques) in laser weld inspection, and summarized attempts to utilize artificial intelligence. AI) welding quality identification technology. In addition, the University of Kentucky Welding Research Laboratory [21] systematically analyzed a three-step approach to advanced weld manufacturing: i) pre-design, where the process and joint design are selected based on the available processes, ii) design that uses a model to predict the outcome of a given set of welding parameters, and iii) real-time sensing and control to overcome deviations in welding conditions through parameter adjustment based on on-site monitoring and adaptive control. In fact, most of the mentioned studies mainly demonstrate the ability to measure relevant features and investigate the effect of welding parameters on these measured quantities. In addition, optical sensing technology is mainly chosen for in-situ, real-time monitoring of LBW processes due to its non-contact, intuitive, integrated, flexible and versatile advantages. In fact, in the mainstream literature, the key term “monitoring” is used to denote field data collection, feature extraction, and dynamic process modeling. From a statistical point of view, the term “monitoring” refers not only to data collection, but also to the identification of processes/defects through automated alarm rules [23]. This monitoring approach is needed to really improve the intelligence capabilities of the next generation of LBW systems. Therefore, the scope of this review is mainly focused on optical process monitoring, involving observational, experimental, and system information gathering, with a particular focus on the discussion of: in-situ sensing techniques, multi-feature characterization, and process modeling.

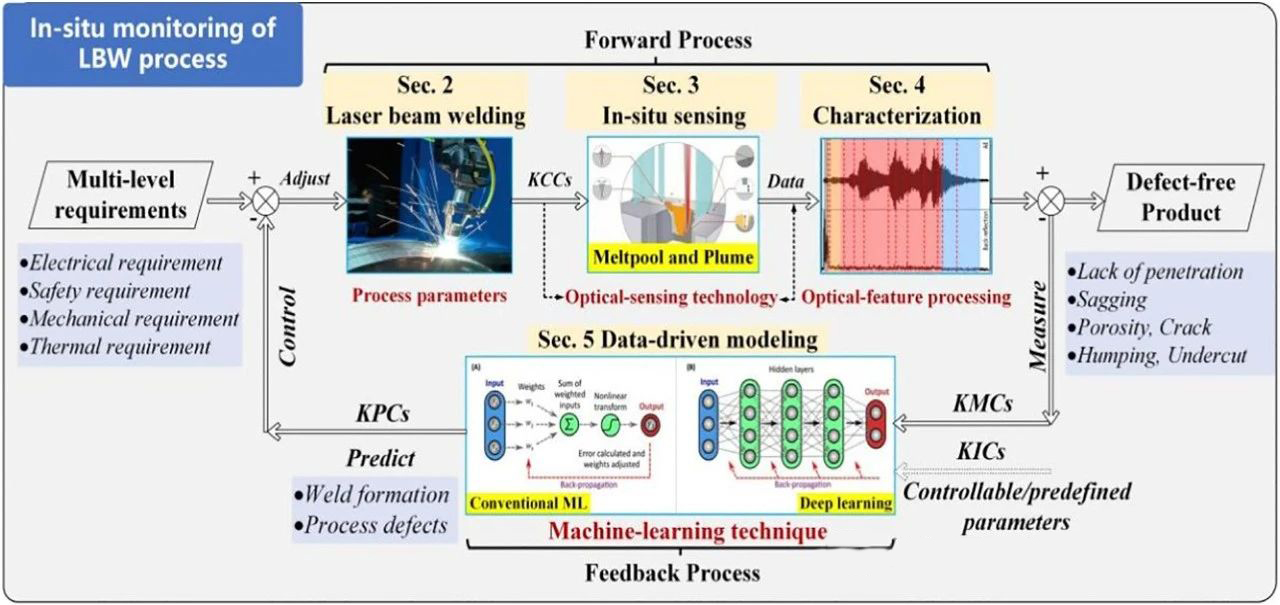

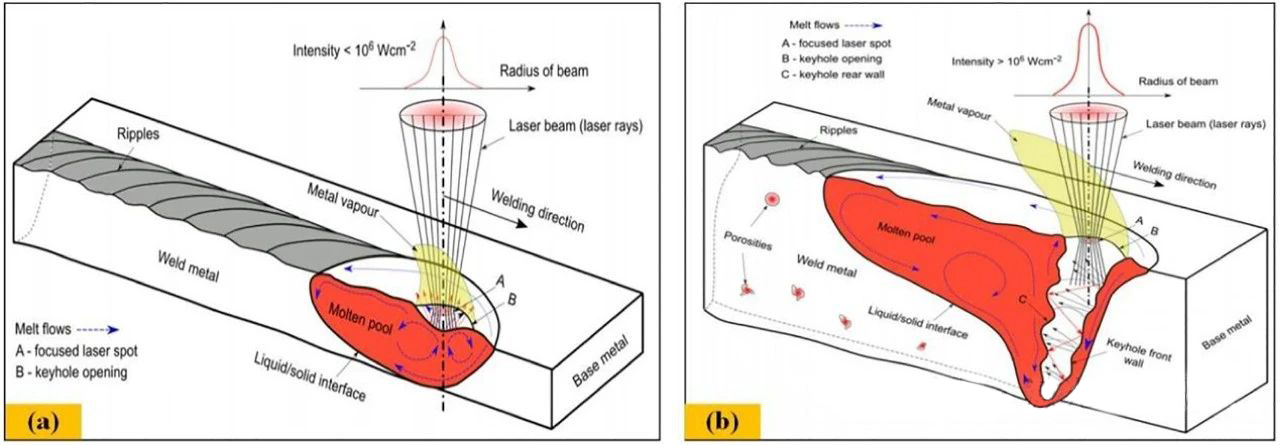

Picture of the paper

Figure 1. This review reviews the flow chart of the on-site monitoring process of advanced laser beam welding manufacturing

Figure 2. Schematic diagram of the physical principles of the laser beam in the laser beam welding modes of conductive welding and (b) small hole welding

Figure 3. Schematic diagram of laser beam small hole welding during full penetration (a) and (b) examples of common welding defects

Figure 4.The interrelationship between process parameters, process characteristics and process quality

Figure 5.Multi-wavelength in-situ optical sensing technology in the LBW process

Figure 6.Schematic diagram of the optical monitoring system and different optical radiation bands

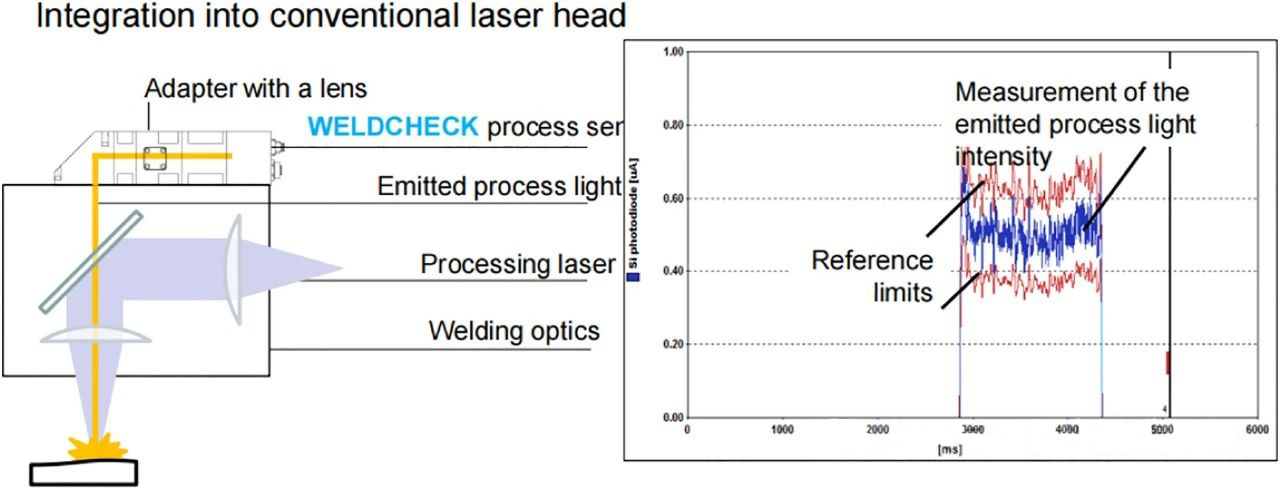

Figure 7. Optical sensing system integrated into conventional laser heads

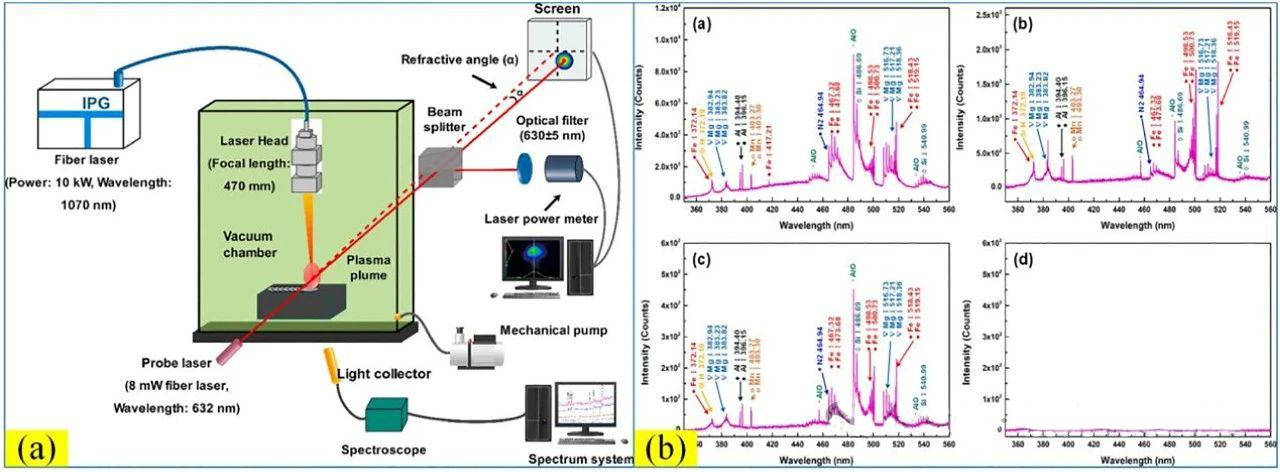

Figure 8.Schematic diagram of the spectroscope measurement system (a) and plasma plume spectroscopy (b) during laser vacuum welding

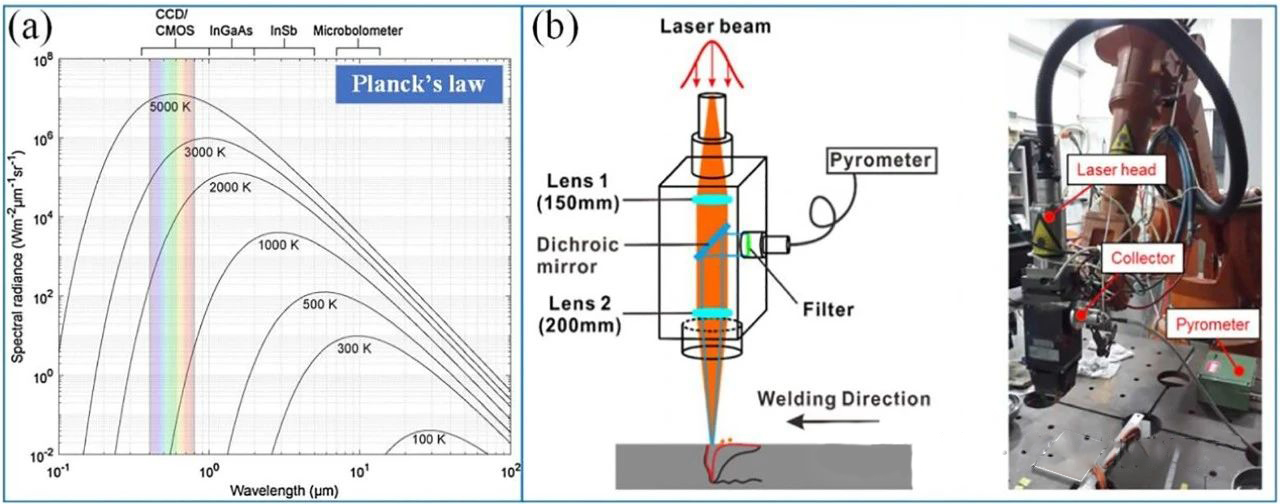

Figure 9.(a) Spectral emissivity of an ideal blackbody at different temperatures and (b) Coaxial temperature monitoring system with pyrometer sensor

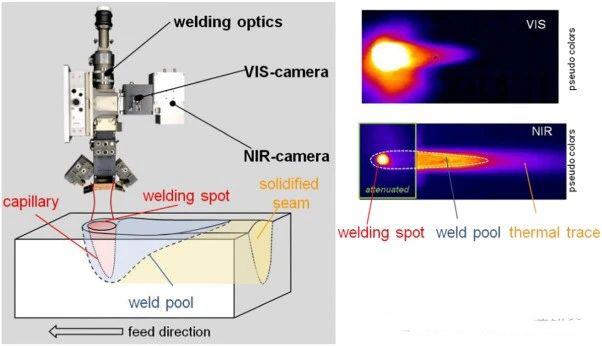

Figure 10.The weld zone of deep penetration welding basically consists of three areas: the capillary at the solder joint location, the liquid weld pool, and the solidification weld

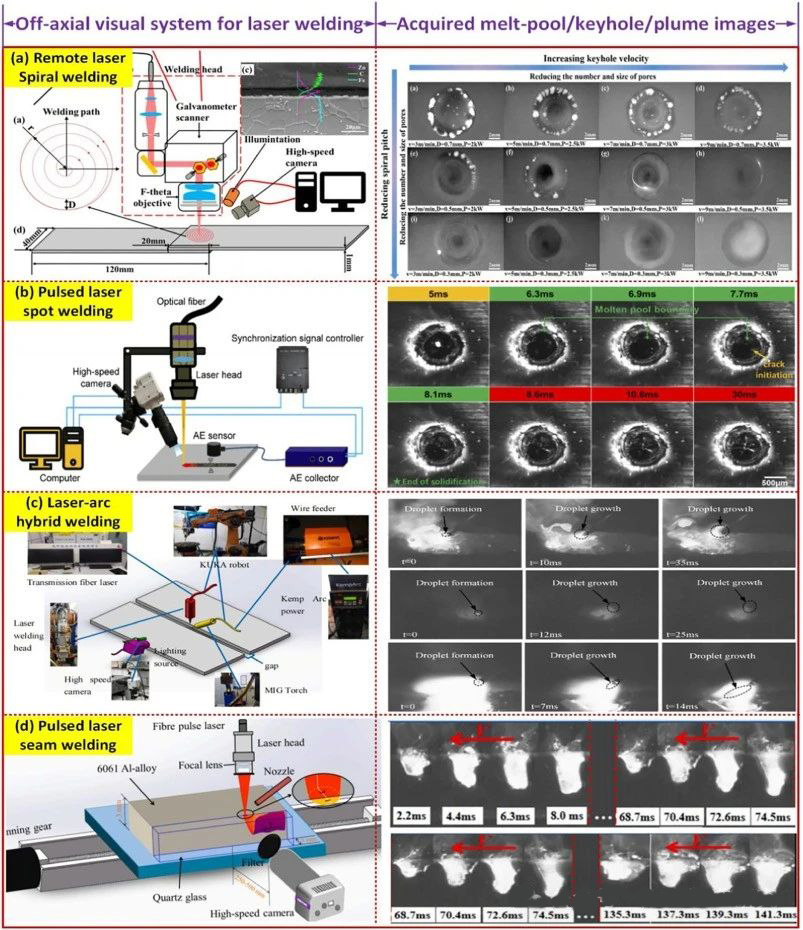

Figure 11.An off-axis vision sensing platform developed to capture images of holes, weld pools, and plumes in laser-based manufacturing processes: (a) remote laser welding, (b) pulsed laser spot welding[;( c) Laser arc composite welding]; (d) Pulsed laser seam welding

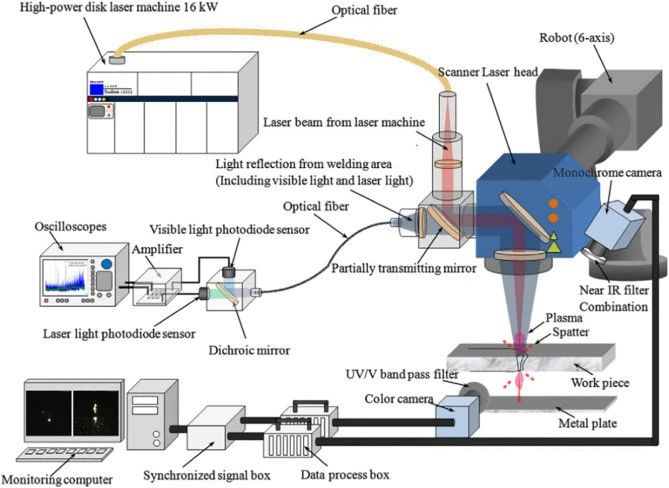

Figure 12.Schematic diagram of multi-optical sensing for disc laser welding

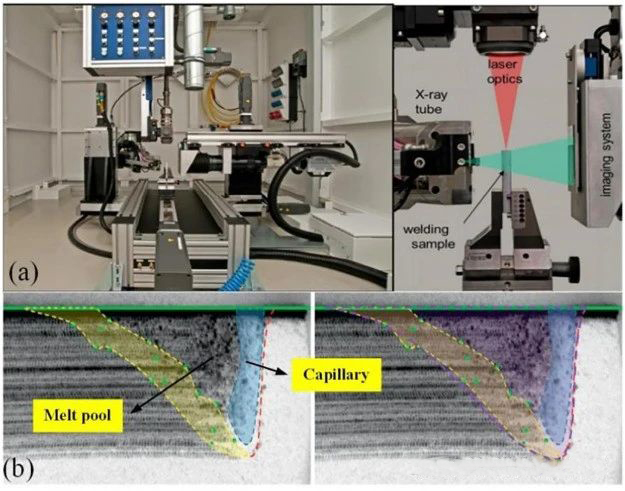

Figure 13. (a) Welding experimental facility with on-line X-ray observation and (b) Typical X-ray image of a capillary laser welding process

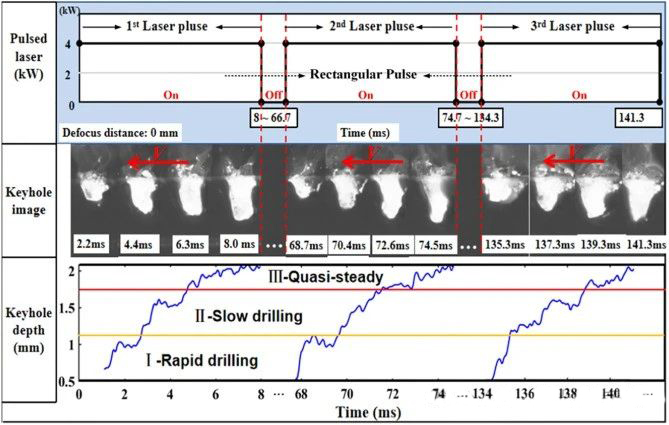

Figure 14. Fluctuation of hole depth during pulsed laser welding based on metal-glass “sandwich” imaging technology

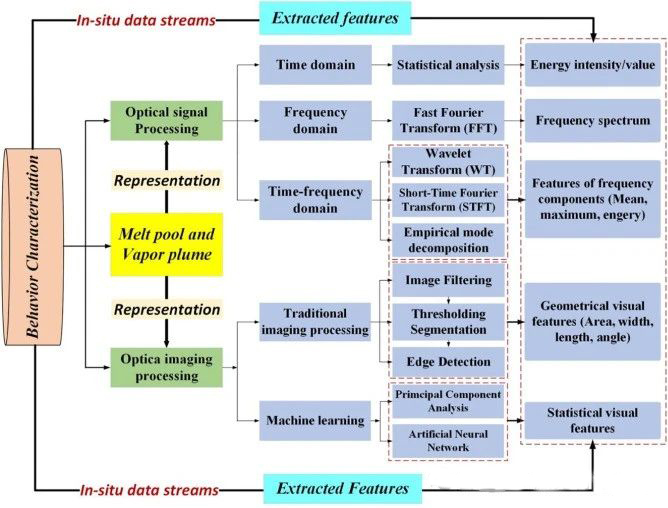

Figure 15. Overall classification of behavioral characterization techniques in LBW processes

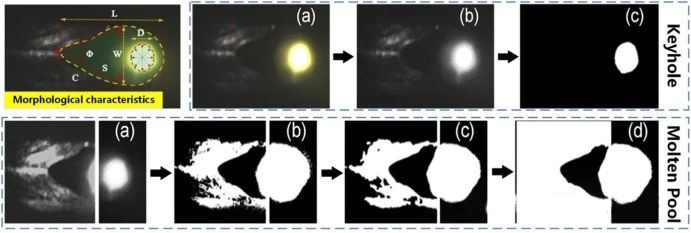

Figure 16. Image processing flow of melt pools and holes

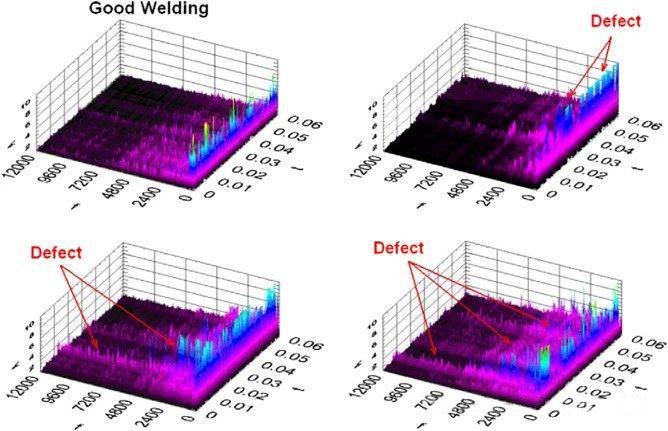

Figure 17. Defect detection in time-frequency analysis of laser welding

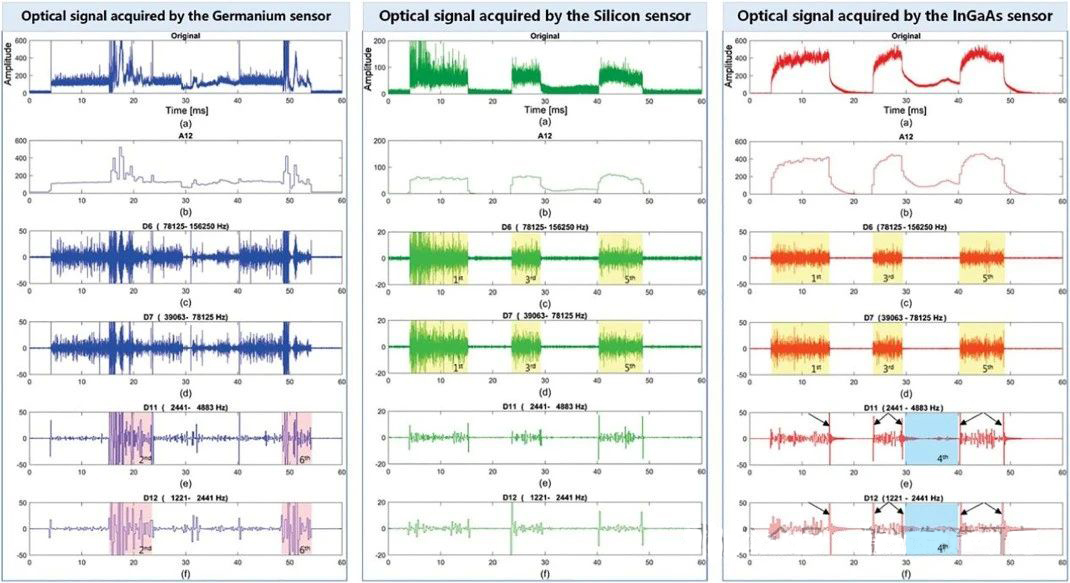

Figure 18. Wavelet decomposition of several levels of decomposition of optical signals acquired by different sensors

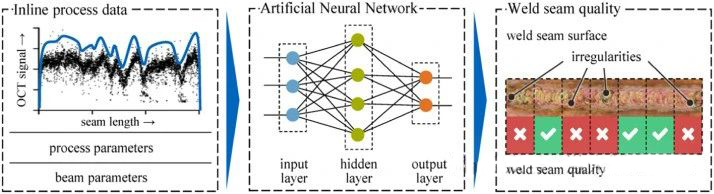

Figure 19. Weld quality prediction based on OCT data and ANN models

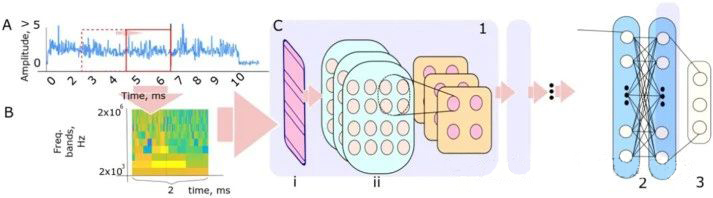

Figure 20. Supervised deep learning for real-time quality monitoring of laser welding

There is a growing body of research in the literature aimed at understanding the nature and processes of LBW, their effects on product quality, and how these effects can be mitigated or avoided by acting on several controllable parameters. In fact, the lack of robustness and stability of the metal LBW process has been widely pointed out as a major issue that warrants considerable research effort and technological progress. The development and implementation of on-site monitoring solutions is a priority to drive breakthroughs in the industrialization of LBW systems. This review summarizes some of the following conclusions:

1) In-situ sensing is proposed for different observable features, including molten pool, plasma plume, and splash. Other in-situ NDT systems are currently under development, such as optical coherence tomography, X-ray, and may be implemented and tested in the near future.

2) Based on optical radiation and visual sensing technology, advanced image/signal processing algorithms are widely applied to extract key features and describe the salient features of laser physical phenomena.

3) Recent developments have led to advanced process monitoring systems that integrate machine learning techniques for weld formation prediction and defect diagnosis to control weld quality. More and more researchers are introducing deep learning to analyze raw information and extract complex features of the laser welding process.

While these are all areas that are currently being studied, there is still a lot of room for the development of new process monitoring methods. As this field matures further, we will undoubtedly see further advances in the combination of in-situ sensing methods being developed as well as characterization and process models. Each development is expected to improve the reliability and stability of the LBW process, unlocking the full potential of smart and sustainable manufacturing technologies across various industry sectors.

Thesis information

Progress and perspectives of in-situ optical monitoring in laser beam welding: Sensing, characterization and modeling

https://doi.org/10.1016/j.jmapro.2022.01.044

The copyright of this article belongs to the original author, only for communication and learning, and the final interpretation right belongs to this official account.